From Walls to Resources: Early Results in AI-Powered Building Deconstruction Planning

Picture walking through a building scheduled for demolition. Traditionally, those walls would be reduced to rubble and sent to landfills. But what if we could see through them, understanding their composition and value before a single hammer strikes?

The Global Construction Waste Challenge

The construction industry generates over 3 billion tons of construction and demolition waste (CDW) worldwide annually, accounting for approximately 36% of total global waste production. According to recent estimates, the United States generates about 600 million tons of construction and demolition debris yearly, with a more promising recycling rate of approximately 75%. This waste represents a significant environmental burden and a lost economic opportunity worth billions of dollars in recoverable materials.

Our Approach

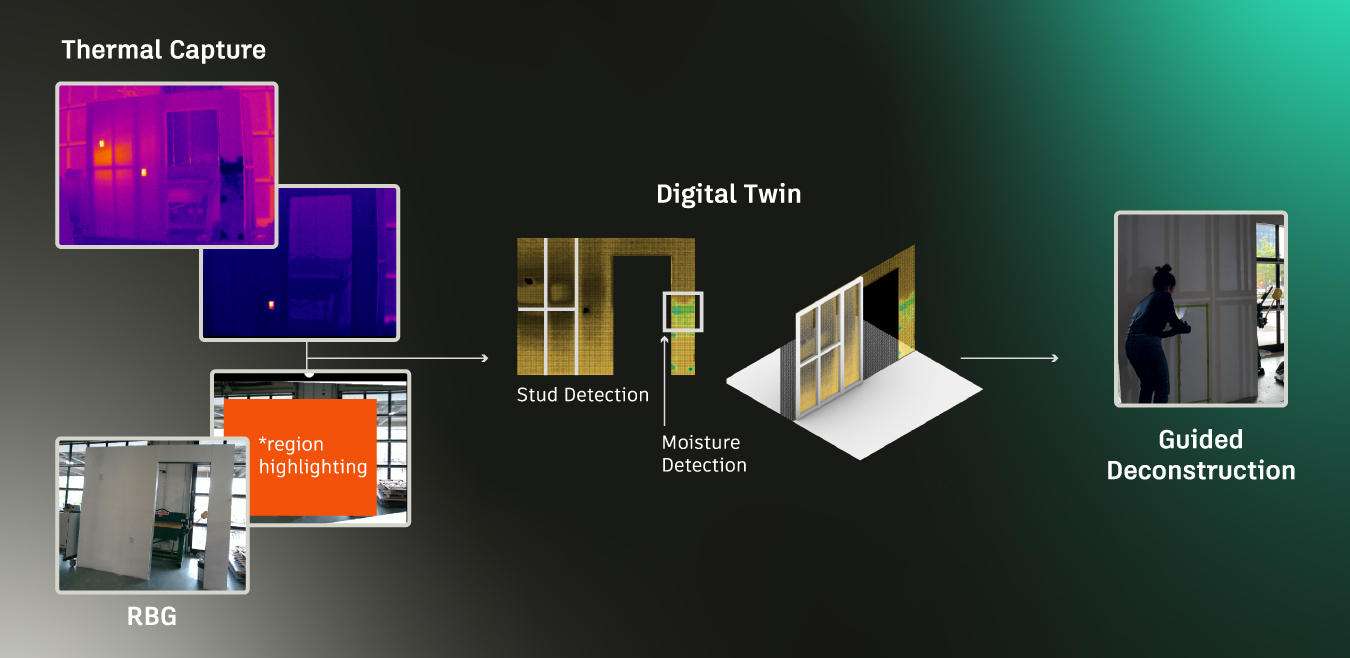

Autodesk Research is developing and testing a system that combines limited multimodal data like thermal imaging, radiofrequency, and GIS data with machine learning techniques to evaluate building materials non-destructively. Like a doctor uses advanced imaging to diagnose a patient, our technology aims to peer beneath the surface of walls, detect studs and other hidden elements, assess material conditions beneath wall surfaces, and identify reusable materials with remarkable accuracy.

“One of the most exciting aspects of this research is its grounding in real-world construction site feasibility,” says Sophia Cabral, a graduate student at the Harvard Graduate School of Design and a former Autodesk Research intern who worked on this project. “We developed implementation methods for both manual and automated deconstruction processes. This means the technology can be used by crews without access to advanced automation technologies while also laying the groundwork for integration with robotic tools in the future.”

Promising Early Results

Initial experiments showed promising results, with our multi-modal sensors scanning the interior walls at the Autodesk Technology Center in Boston. The system achieved 95% accuracy in detecting metal studs under controlled conditions. We assessed the economics in a case study of a high school demolition project, focusing primarily on drywall recovery. In our analysis, a test section was projected to generate $121 in value from intact drywall panels that could be reused directly in new construction rather than incurring $102 in disposal costs as demolition waste. This approach of whole-panel recovery would also prevent approximately 40.5 kg of CO2 emissions by eliminating the need to manufacture new drywall, reducing landfill impact.

When scaled to the annual waste of the construction industry, the impact is staggering. Construction activities account for about 39% of global energy-related carbon emissions, with 11% directly attributed to materials and construction processes. If adopted in just 10% of demolition projects worldwide, this technology could prevent millions of tons of CO2 emissions yearly while recovering billions in material value.

Real-World Impact

This research opens possibilities for more precise material recovery in the construction industry. For construction and demolition companies, this means transforming waste management from a cost center into a potential revenue stream. For environmentalists, it signifies a crucial step toward circular construction practices. For society, it showcases how artificial intelligence can help address our most pressing sustainability challenges.

The technology also shows promise for additional applications beyond demolition planning. These include pre-renovation building assessment to identify salvageable materials, historic building documentation and preservation planning, and disaster recovery and structural assessment after floods or fires.

In addition to applications in the circular economy, we see our technology as applicable to building energy retrofits. An automated understanding of material composition within walls enables the simulation of heat exchanges between rooms, the prediction of energy consumption in older buildings, and informed decision-making about potential upgrades and redevelopments.

Looking Ahead

The future of construction doesn’t have to mean more landfills. With AI-powered deconstruction, every building becomes a material bank, waiting to be reinvested in our future infrastructure. We’re continuing to improve the system’s capabilities and reliability. The goal is practical tools that help make building deconstruction more sustainable and economically viable. This study represents a first step toward that future.

Read the full research paper: “A Contactless Multi-Modal Sensing Approach for Material Assessment and Recovery in Building Deconstruction”

Get in touch

Have we piqued your interest? Get in touch if you’d like to learn more about Autodesk Research, our projects, people, and potential collaboration opportunities

Contact us