How Kit Switch works with Autodesk to Bring Efficiencies to Design and Make

Creating modular interiors for sustainable building reuse

One out of 10 apartments needs to be rehabilitated immediately. How can the country have accumulated so much deferred maintenance? What does it say about our design and construction practices?

Lack of predictability.

The number one cause of construction delays are budget inaccuracies at the project start. This lack of predictability is the main reason property owners end up postponing rehabilitation work. It is a recurring challenge in construction as a whole; one that companies like Autodesk have been tackling through software tools for years and one that a startup called Kit Switch is now solving for the retrofit and reuse industry.

“Can you do this? Really?” – This is what our team at Kit Switch hears most frequently when we show the results of our work to developers and builders.

“Can you do this? Really?” – This is what our team at Kit Switch hears most frequently when we show the results of our work to developers and builders.

I’m one of the two co-founders of Kit Switch, a women-led business based in San Francisco using productization and design-for-manufacturing to bring efficiencies to the design and construction of building interiors for our new and existing buildings. All our houses hold a level of complexity that many of us overlook.

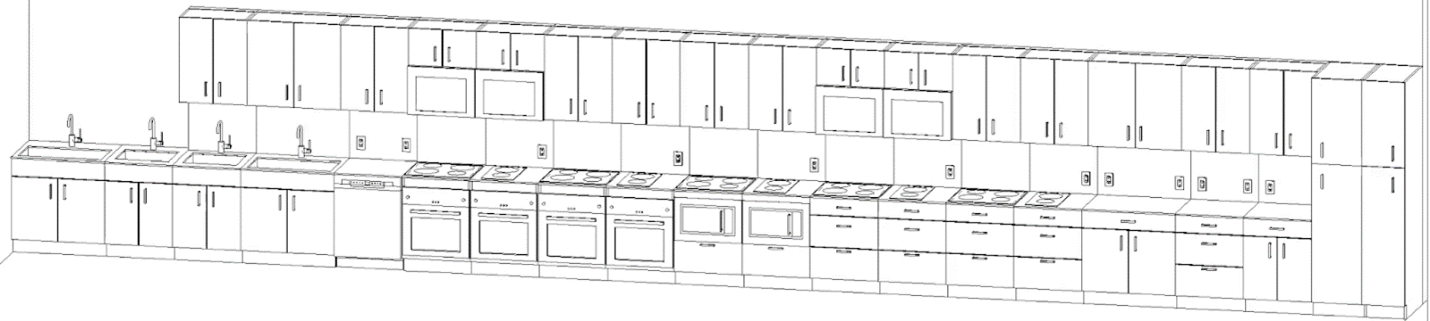

Take a look at your apartment, specifically, the kitchen. What do you see? Cabinets of different widths and heights, depths. A countertop cut out in the exact right spot for your sink and your faucet. Maybe you have tiles covering your entire backsplash, or maybe it is a small 4-inch piece made of the same material as the countertop. Either way, you will probably notice the presence of a few outlets throughout the width of the backsplash. The list is long. Think about all the appliances, their different voltage requirements. Think about the lighting fixtures, the threads of cabling. And everything else that makes your kitchen functional and aesthetically pleasing. This is not an exhaustive list, yet it is already highly complex. It takes a lot of experience for project managers and superintendents to coordinate schedules for so many different trades and materials, and ultimately stick to the budget.

This is just the construction component. Now imagine what must happen when the kitchen needs to be fixed 15 years down the road. Who will property managers call when this intricate assembly needs to be rehabbed? How long will it take?

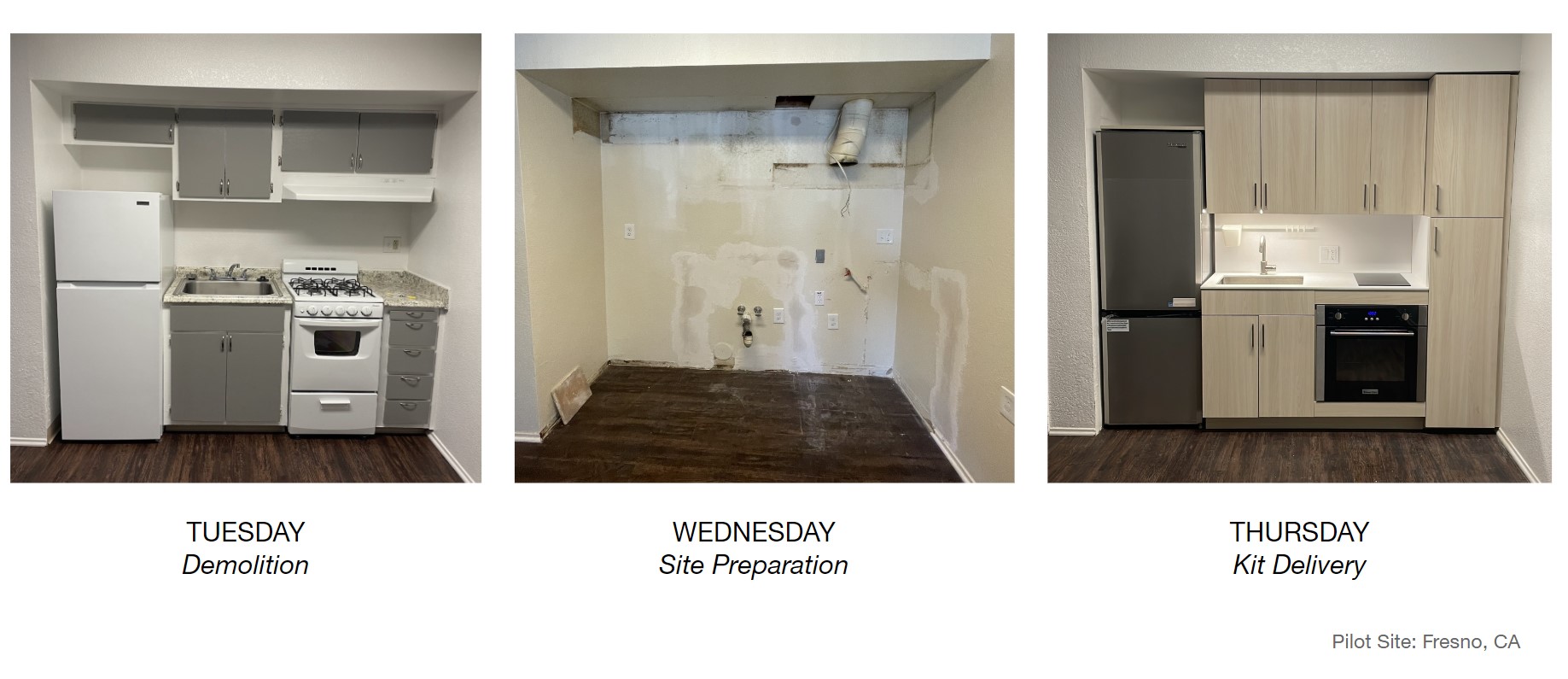

It will take weeks. It takes weeks to build interiors and it takes weeks to rebuild them. For tenants, it means weeks of relocation to another building, another district, sometimes another city. For owners, it leads to weeks of lost rent or relocation fees, adding up to thousands of dollars. Even $2,000 of budget overrun for a studio kitchen rehab is more than 10-20% of the initial budget. No wonder why these projects are not happening.

But what if you could demolish and rebuild a kitchen in two days? What if we could retrofit a 50-unit apartment building without relocating tenants at all?

This “what if” is the future Kit Switch unlocks. Kit Switch is a product designer and logistics coordinator. Owner-developers get to design interiors by selecting from our library of interior products, all offered at an upfront price. Using the Kit Switch library, their architects can drag-and-drop 3D models of our products into their project file to create kitchen, bathroom, and storage kits for different unit types in the building. Kit Switch bridges design to manufacturing. Our prefabricated products are assembled by certified manufacturers in less than 8 weeks and get delivered to the jobsite for installation by trained contractors.

Kit Switch is a product company first and foremost. Whereas we have been focused on standardizing products for a specific use case, Autodesk is a software company developing tools across use cases, which has made this collaboration all the more valuable. Throughout our residency at the Autodesk Technology Center in San Francisco, we have been developing workflow integrations for architects and for manufacturers. For our first product lines, we tested the design-to-manufacturing workflow ourselves, using Autodesk software to design and building our own prototypes in the workshop. Now, learning from our project collaborators – architects and general contractors – and from our manufacturing partners, we are digitizing these workflows and unlocking paths toward automation. As more productized solutions get to market and scale, Autodesk teams are paving the way for what the industry will need. Our team looks forward to parameterizing our products further as we scale, in order to broaden our impact all while keeping the efficiencies built into our product management and coordination workflows.

Since day one of starting Kit Switch, we prioritized coalition building. A strong ecosystem of complementary capital and accelerators has been instrumental in getting our products to market. The Autodesk Research Residency Program is one of many programs we’ve benefited from along the way. Like us, many innovators in the built environment have to think through developing software solutions, building physical products, or a hybrid of both. When doing so, finding the right physical workspace can be a challenge. The Autodesk Technology Centers combine both physical coworking space with machine shops and showcase areas, and digital support through software tools and a network of experts. We have also found tremendous support through programs like the Housing Venture Lab accelerator at Terner Labs, which offered access to an extensive network of advisors, strategic partners, regulators and policymakers. We’re excited to see new programs emerging to support the next generation of innovators, including Terner Labs’ new Builders Lab, which will focus on supporting AEC innovators in scaling efficient, cost-effective and sustainable methods of housing delivery across the U.S. (applications are open now through August 2 – find out more here).

Candice Delamarre is the COO and Co-founder of Kit Switch.

Get in touch

Have we piqued your interest? Get in touch if you’d like to learn more about Autodesk Research, our projects, people, and potential collaboration opportunities

Contact us